FORTUNE PARTS INDUSTRY PUBLIC COMPANY LIMITED

Fortune Parts Industry

Fortune Parts Industry (FPI) provides one stop service for Automotive Manufacturing Services. We started as an automotive replacement parts manufacturing with substantial experiences in automotive field. We continued to expand the production base to the body parts factory which is a vertically integrated company with world-class factory standards. Our services are Plastic Injection Molding, Chrome Plating, Painting, Designing, 3D Printing, Molding, and FPIS (Environmental Consulting)

With 30 years of experience, professional expertise, a strong client base, and the use of advance technology, FPI manifested that a continued development has enable FPI to meet customers’ requirements.

Our main product lines mainly focus Japanese pickup, truck, personal cars, and all major brands of Japanese car - Toyota, Nissan, Isuzu, Mazda, Mitsubishi, Hino, Honda, Suzuki, Smart, Samsung, Daewoo, Hyundai, and Kia.

With over 30 years of experience in the automotive industry

We have a complete

production process

We produce and provide

OEM and REM customers

Product quality complies

with international standards

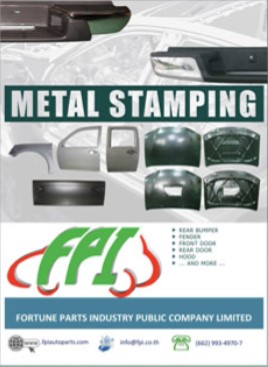

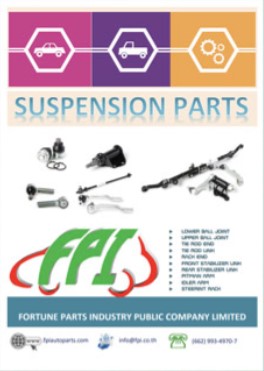

Our capability in the design and manufacturing industry of plastic mold, inclduing plastic molds of auto parts has earned an excellent reputation. The success and growth over the years have proven that we have accomplished our goals, and we have rich experience in automotive part manufacturing industry.

Fortune Parts Industry is always able to provide the best techincal support, products and services related to automotive parts to our customers Our company has highly skilled and experienced professionals in automotive industry, and we use the latest technology to consistently create products with outstanding quality. Various processing is our strength. With over 800 employees, large injection machines, the highest technology of ABS chrome plating process, 2K painting process, we are able to handle large volumes and achieve a variety of projects.

Fortune Parts Industry provides a full range of product design and manufacturing services for automtive parts, starting from mold design, plastic injection, chrome plating, painting, to verifying from international standards certifications such as ISO9001, IATF16949, ISO14001, ISO50001 and ISO45001. Various processes are designed to adapt to business growth related to automotive industry, electrical appliances, and sanitary ware, located in the same area of 9,000,000 square meters. We also have standard machines and equipments to design and manufacture the products.

Highlight of our Services

- Plastic Injection Molding

Injection molding machine can produce from 100 tons – 2600 tons, production capacity 9,775 tons/year. - Plastic Chrome Plating

Chrome plating process on ABS plastic surface works with standard electrical system from Japan and Europe. This plastic chrome plating can plate large workpieces up to 2 meters and can be plated up to 48 microns thick, with a production capacity of 60 million square decimeters/year. - Plastic Painting

Painting process, 2K closed system at 300,000 class with a capacity of 53 million square decimeters/year. - Designing and Molding

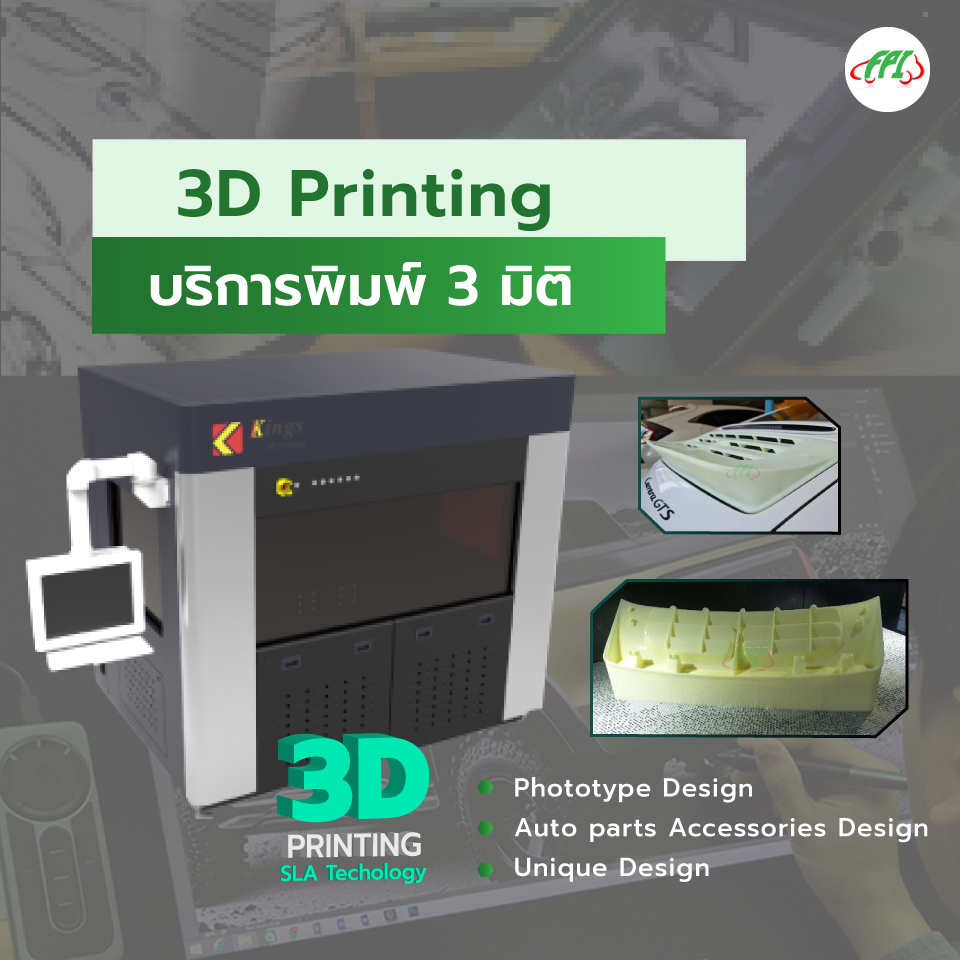

Designing and making large mold - 3D Printing

Industrial SLA (Stereolithography) printers use a photosensitive resin material, which molded by laser. The highlight is the outstanding result that comes out with a smooth surface, high quality, and excellent detail. This printer can print large sizes from 300mm.-1,700mm.

International Standard | Certificate of Registration

- IATF 16949: 2016 | Automotive Quality Management System

- ISO 9001: 2015 | Quality management system

- ISO 14001: 2015 | Environmental management system

- ISO 50001: 2018 | Energy management system

- ISO 45001: 2018 | Occupational health and safety management system